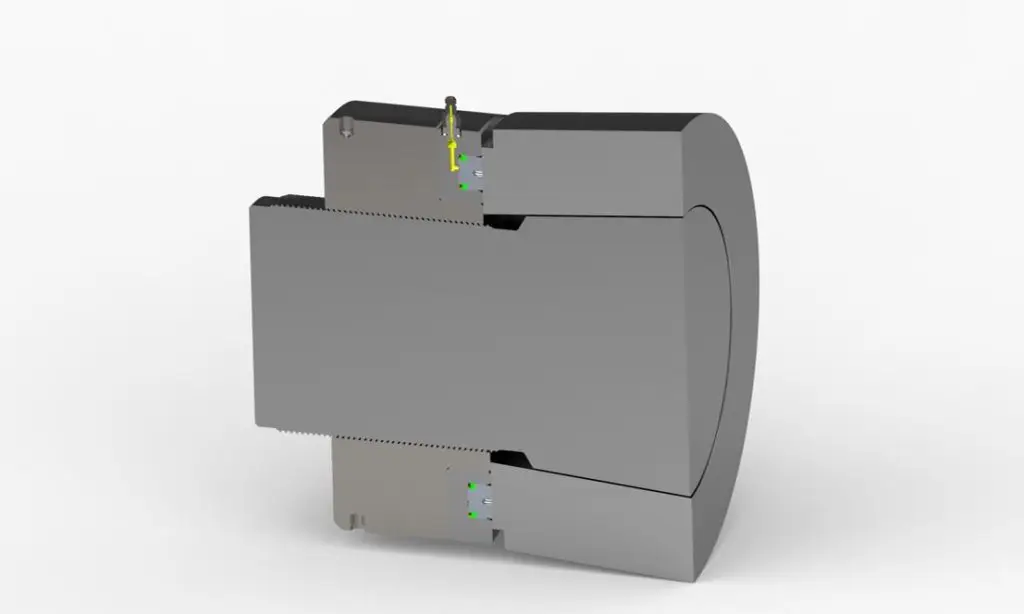

The RingJack, a nimble counterpart to the Pilgrim Nut, is engineered for seamless integration onto a client-provided fixing nut. Its design is ideal for the critical task of affixing propellers within typical ship propulsion or steering systems, ensuring both axial push-up and exact positioning. Customizable to the application’s needs, the Pilgrim RingJack can be supplied with either a plain bore or threaded configuration. The product line spans a versatile range of sizes, with standard bores measuring between 245 mm and 720 mm, catering to a broad spectrum of maritime engineering demands.

can be removed and installed many times without sapes.

Safe and operator friendly, providing quick mounting and dismounting, removing uncertainty.

Increases profit by reducing unplanned costs through reliable dismounting, allowing for accurate planning.

Delivers known and reliable axial displacement providing peace of mind.

Begin by positioning the JackNut onto the fixing nut, either by placing or screwing it on. The RingJack nut mirrors the Pilgrim Nut’s operational principle, harnessing the power of pressurized hydraulic oil. This oil is delivered by the reliable Pilgrim Mk12 MorPress hydraulic pump, connected via a quick connect. The pressurized oil then propels the RingJack’s piston axially, ensuring the component is pushed up the taper accurately, achieving the precise final positioning required.