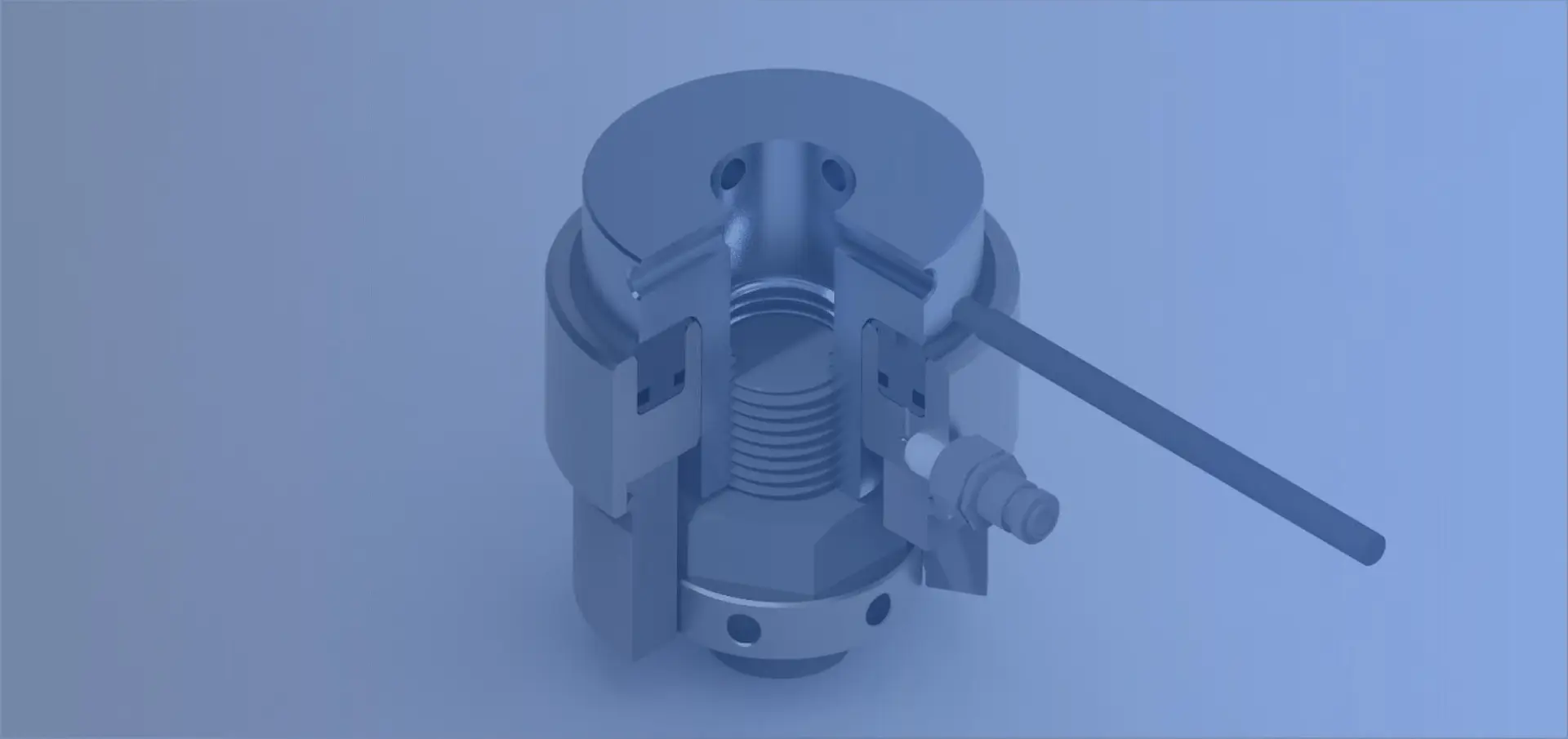

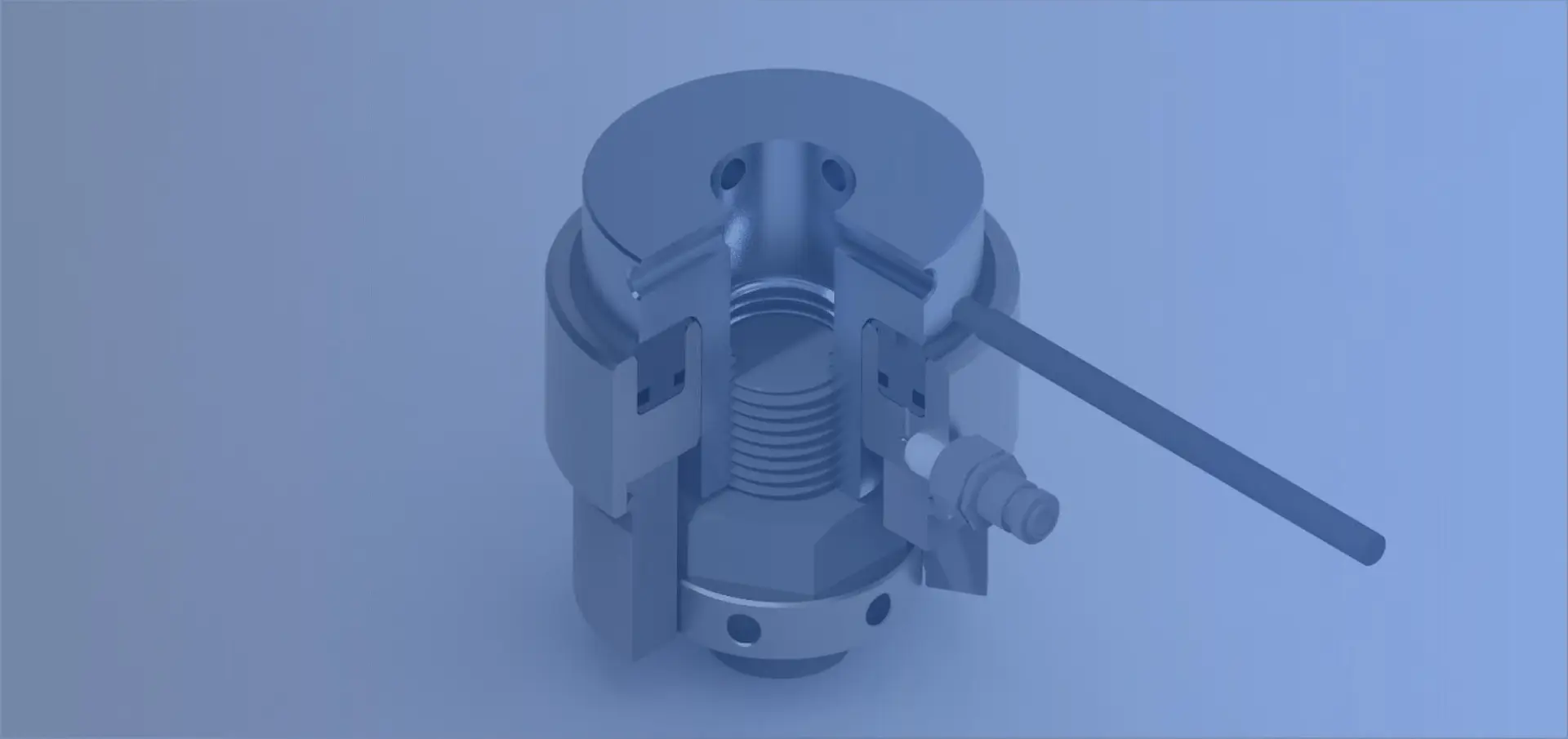

This engineered bolt, featuring a built-in hydraulic load cell, is a game-changer in industries that demand a significant retained load. Its design is tailored for seamless integration into both blind and thru holes, delivering a precise pre-load that preserves the integrity of the application, free from the damage often caused by traditional bolts. The bolt’s versatility is further showcased in its three distinct designs—shim, top locking, and bottom locking collars—each ensuring an effortless installation and removal experience. This bolt solution represents the epitome of engineering ingenuity, combining neatness and adaptability for a wide range of industrial applications

Ideal for blind hole applications with threads of M36 upwards. Its ideal for either static or slow rotating applications.

The built-in load cell enables this bolt to be used in applications with reduced access.

This bolt can be tightening homogeneously, providing shortened fitting time while ensuring accurate a secure tightening.

Designed for installation and removal speed this bolt solution takes approximately 15 minutes to install. Its is also totally re-usable.

Insert the bolt into the designated hole and initiate hydraulic pressure within the load cell. This action causes the load ring to shift axially, effectively stretching the bolt. This stretch is crucial as it allows for a secure locking mechanism, whether by shim or locking collar. After the hydraulic pressure is relieved, the bolt maintains the pre-set retained loads, signifying a successful and accurate installation.