Tailored to meet your unique requirements, the Pilgrim Bolt Tensioning Kit (BTK) is available in various configurations to align with the specific needs of each customer.

Each kit is meticulously assembled, containing all the necessary tools for a complete RadialFit Bolt or ClampBolt installation and removal. The BTK is intuitively designed for ease of use, enabling the installation of individual bolts or simultaneous installations with a dual Bolt Tensioning Kit.

The dual BTK feature is particularly advantageous, allowing for the pressurization of two bolt assemblies at once, which significantly cuts down maintenance time during both major and minor shutdowns. The hydraulic heads included in the BTK comply with the European Pressure Equipment Directive and bear the CE mark, assuring you that Pilgrim’s products adhere to the highest international safety standards. This commitment to quality and safety is at the core of Pilgrim’s mission to deliver reliable and efficient solutions to our clients.

Certified to European Pressure Equipment Directive.

Ergonomic design to aid operator safety and comfort.

Pilgrim treat its bolt tensioning kits for corrosion resistance, prolonging the tools life.

Flight case style tooling box for secure and safe storage, with engineered foam insert

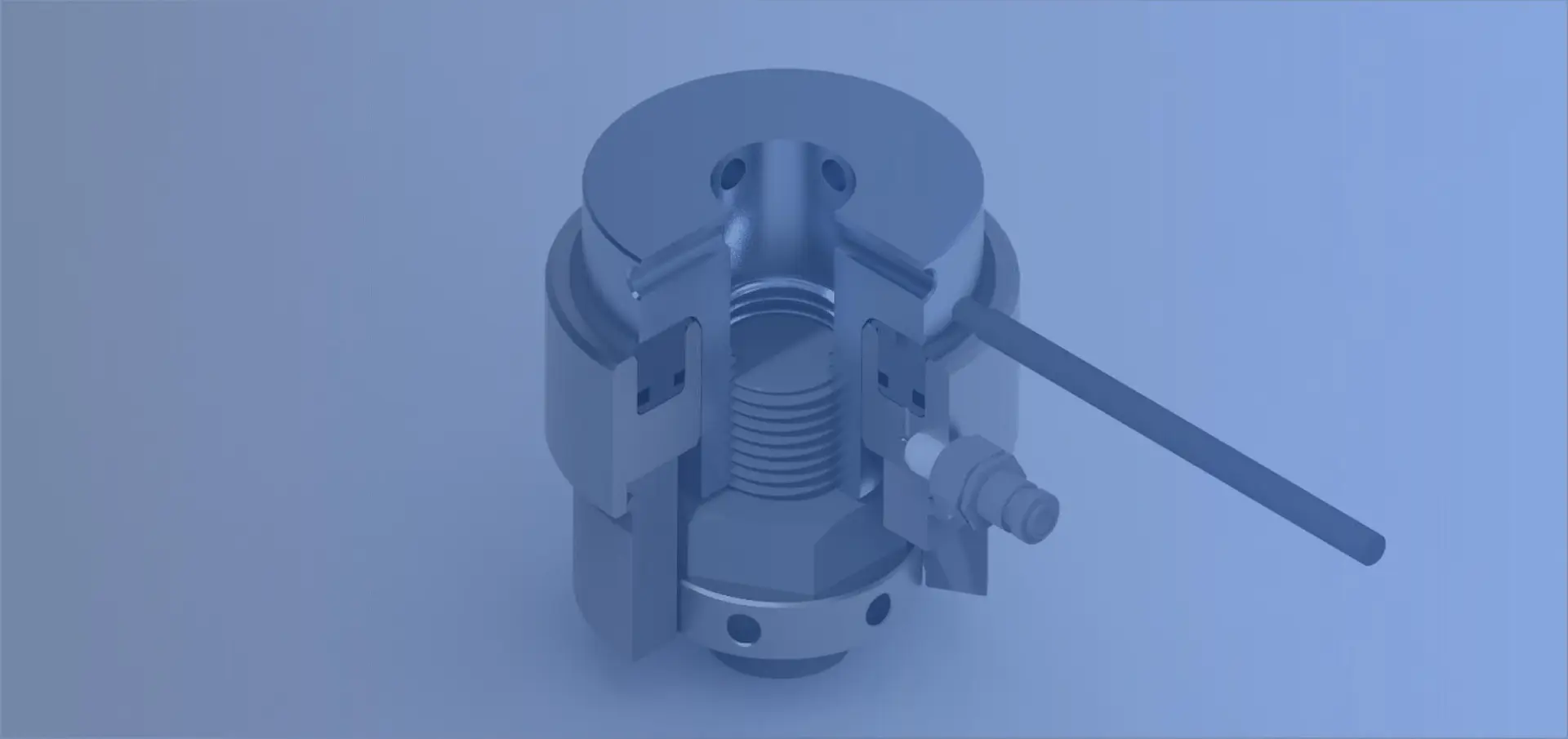

Typically bolt sleeves are provided oversize and machined on-site to match the holes, using a mandrel provided in the BTK. Also a kit typically includes components such as a puller, tensioning head, setting bridge, removal bridge, tensioning bridge, and an oil injection adapter.

The process involves fitting round nuts and tightening them with minimal pressure, assembling the tensioning bridge, nut rotating ring, puller, and hydraulic head onto the bolt as per the assembly drawing. The hydraulic head is pressurized to the tensioning pressure, and the applied extension is recorded. The system is held at pressure for a specified duration, usually around one minute, to ensure proper tensioning.

The bolt tensioning kit is often used with a hydraulic pump, such as the MK12 Morpress Air-Driven Hydraulic Pump, which provides the hydraulic power needed for bolt assembly and disassembly. The puller, which is used exclusively on the Compact design of bolts is a critical component, manufactured from high-strength materials to withstand the stresses of operation and ensure safety and efficiency.