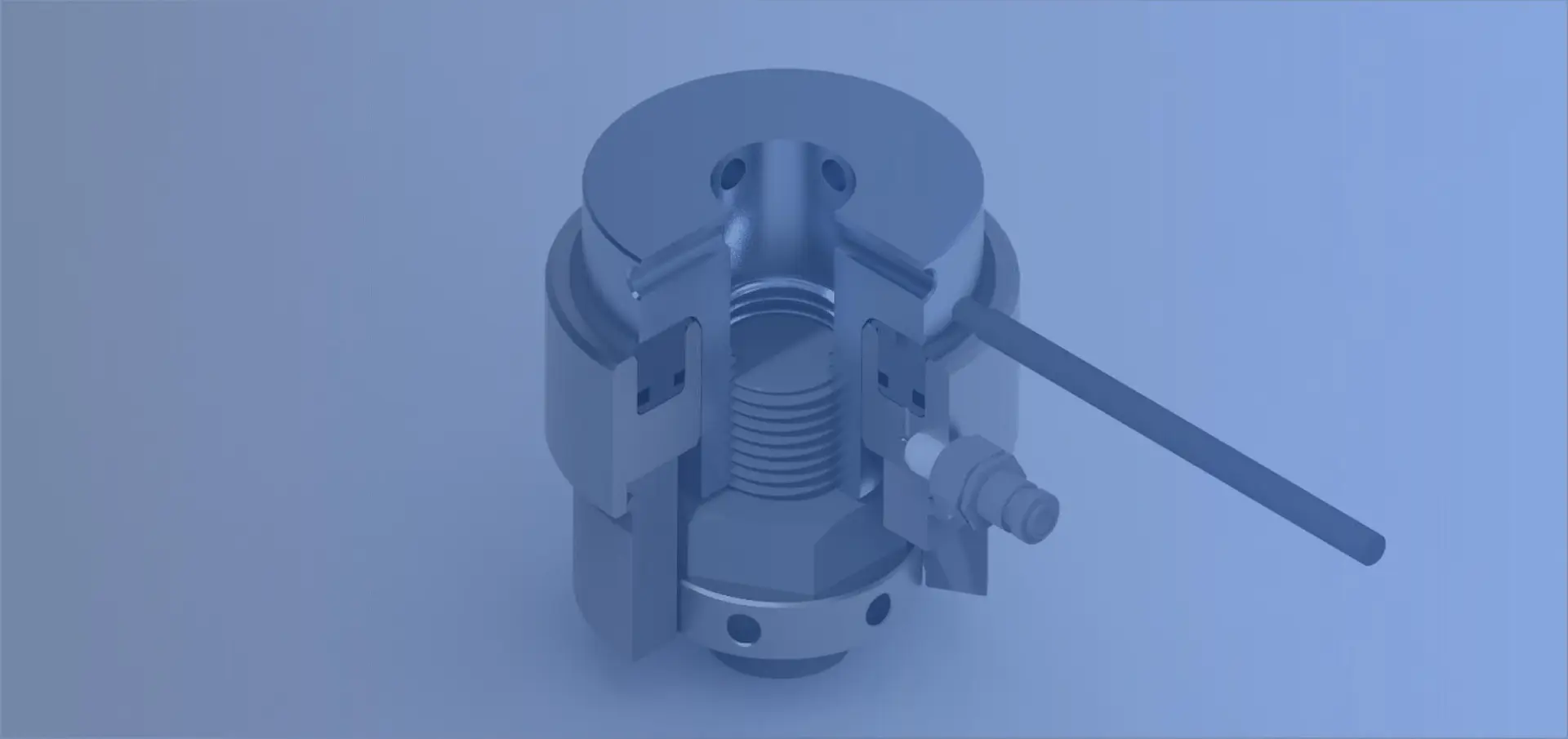

The Datum Plug from Pilgrim provides confidence in measuring accurate bolt length, which can be taken before and after hydraulic tensioning to verify that the installation and axial loading has been undertaken correctly.

As with most types of bolts, turbine coupling bolts look much the same whether they have been tightened or not. To provide the optimum in simple accurate quality control checks Pilgrim has developed the purpose designed Datum Plug system.

Cost effective solution.

Allows for accurate measuring giving assurance that the tightening operation has been completed correctly.

The Datum Plug system consists of a pair of taper threaded plugs manufactured to match the special internal thread in each end of the Radial Fit Bolt. Each plug has a standard hexagon head for tightening to the required 30 Nm. On the top of the hexagon head is a highly accurate and hardened raised face that provides the datum from which the first initial and final tensioned bolt measurement are taken. After hydraulically drawing the bolt through its corresponding sleeve in the coupling hole the datum plug is fitted and the overall length of the bolt is measured and recorded. The final hydraulic tensioning of the Radial Fit Bolt is carried out with the load being retained by tightening of the nuts. The length of the bolt is measured again over the datum plugs and recorded to complete the quality audit. The final bolt length should be greater than the initial measurement with the same procedure carried out for each Radial Fit Bolt in the coupling.